In today’s fast-paced manufacturing landscape, Original Equipment Manufacturers (OEMs) require precise, reliable, and high-quality plastic components to ensure seamless integration into their products. At Innoprime Plast Pvt. Ltd. (IPPL), we specialize in custom plastic moulding solutions tailored to meet the specific needs of OEMs across diverse industries, including automotive, electronics, medical, and consumer goods.

Why Custom Plastic Moulding Matters for OEMs

Every industry has unique challenges, from strict regulatory standards to complex design requirements. Custom plastic moulding plays a critical role in ensuring that each component is designed to meet these specific needs with precision, durability, and efficiency. At Innoprime, we collaborate closely with OEMs to develop moulded solutions that align with their exact specifications, ensuring superior performance and long-term reliability.

The Innoprime Advantage: Precision & Expertise

At Innoprime, we believe in delivering more than just moulded plastic components—we deliver value-driven solutions. Our expertise in plastic injection moulding, combined with state-of-the-art technology and a skilled engineering team, enables us to manufacture high-precision parts that meet industry-specific requirements.

Our Key Strengths:

- Custom Design & Development: We work closely with OEMs to design and manufacture bespoke plastic components tailored to their needs.

- Material Expertise: Our knowledge of various materials, including engineering plastics, commodity plastics, and specialty materials, allows us to recommend the most suitable options for each application.

- High-Precision Moulding: Advanced injection moulding machines and tooling techniques ensure tight tolerances and consistent quality.

- Scalability: From prototyping to full-scale production, we provide flexible manufacturing solutions to accommodate project requirements.

Tailored Solutions for Diverse Industries

At Innoprime, we understand that different industries have unique demands, and we take a customized approach to each project. Our ability to engineer and manufacture high-precision moulded components makes us a preferred partner for OEMs in a variety of sectors:

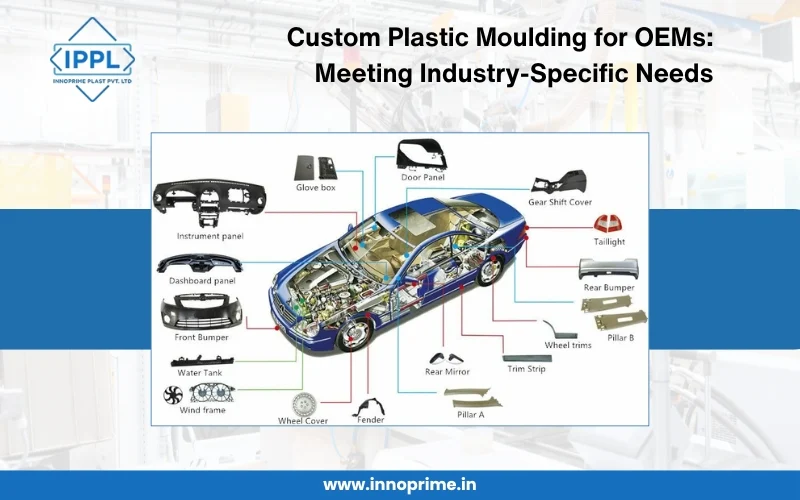

Automotive

In the automotive industry, precision is critical. We manufacture high-quality plastic components that offer superior strength, thermal stability, and impact resistance. Our moulded parts are used in interiors, exteriors, engine components, and electrical systems, ensuring long-lasting performance in demanding environments.

Electronics

With miniaturization and high-performance demands in the electronics sector, we produce precision-moulded plastic enclosures, connectors, and housings that offer durability and electrical insulation. Our expertise in insert moulding allows for seamless integration of metal and plastic components.

Medical & Healthcare

The medical industry requires plastic components that meet strict regulatory standards and biocompatibility requirements. We provide high-quality, sterile, and precision-engineered moulded products used in medical devices, diagnostic equipment, and pharmaceutical packaging.

Consumer Goods

For consumer products, aesthetics, functionality, and durability are key factors. We manufacture ergonomically designed, visually appealing, and long-lasting plastic components that enhance product appeal while maintaining cost efficiency.

Innovation & Sustainability: The Future of Plastic Moulding

At Innoprime, we are committed to continuous innovation and sustainable manufacturing. Our R&D team constantly explores new materials, advanced moulding techniques, and eco-friendly solutions to improve efficiency and reduce environmental impact. We utilize energy-efficient processes and recyclable materials to create sustainable solutions for OEMs, ensuring compliance with evolving industry regulations.

A Customer-Centric Approach

We prioritize collaboration, transparency, and reliability, ensuring that OEMs receive on-time delivery, consistent quality, and excellent customer support. Our motto, 'Right Solutions in Right Time,' reflects our dedication to providing industry-leading plastic moulding solutions tailored to the specific needs of our customers.

Conclusion

At Innoprime Plast Pvt. Ltd., we don’t just manufacture plastic components—we create solutions that drive innovation, performance, and success for OEMs. Our commitment to quality, precision, and customer satisfaction makes us a trusted partner for custom plastic moulding. Whether you need a prototype or large-scale production, we ensure that every product meets the highest industry standards.